Foshan Dechenghezhong Chemistry co.,LTD

No,12 Yuyang 2nd Road, Huchong Industrial District, Nanzhuang Town,

Chancheng District, Foshan City, Guangdong, China

Tel:0086-757-82012410

Fax:0086-757-82012430

Website:http://dchz.en.alibaba.com

E-mail:fsdchz@outlook.com

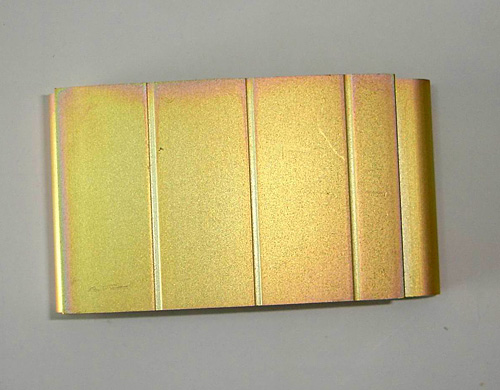

DCHZ-405 Gold Conversion Coating Process for Aluminum

DCHZ-405 is used to produce the maximum corrosion resistant chromate finishes on all aluminum

alloys, can quickly form a gold color conversion film.

Product Characteristic

1. It is easy to control, long life, low cost.

2. Strong adhesiveness, suitable for passivation treatment prior to powder coating or painting.

3.The conversion film has conductivity.

4. Strong corrosion resistance, offers high salt spray resistance of over 100 hours.

Solution Make-Up and Operating Parameters

|

DCHZ-405A

|

5% by volume

|

|

DCHZ-405B

|

5% by volume

|

|

Temperature

|

15-30℃

|

|

Time

|

3-5 minutes

|

|

pH

|

1.5-2.2

|

Finishing Procedure

Degreasing→Rinsing→Etchant or Chemical polishing→Rinsing→Neutralizing →Rinsing→

Conversion coating treatment→Rinsing→Drying (not to exceed 60℃)

Solution Control

The strength of the solution is maintained by adding the concentrate. Dealing with one ton

aluminum will consume 3-5kg DCHZ-405A and 3-5kg DCHZ-405B. The amount of additions

determined by the consumption.

Caution

DCHZ-405 solutions are strongly acidic. Do not get in eyes, on skin or clothing. While preparing

and working with solutions, wear goggles or face shield, rubber gloves and rubber apron. In case of

contact with skin or eyes, flush freely with water for at least 15 minutes. For eyes, call a physician.

Packaging

25kg (net) in plastic bucket.